Our Core Capabilities

Core Production Process

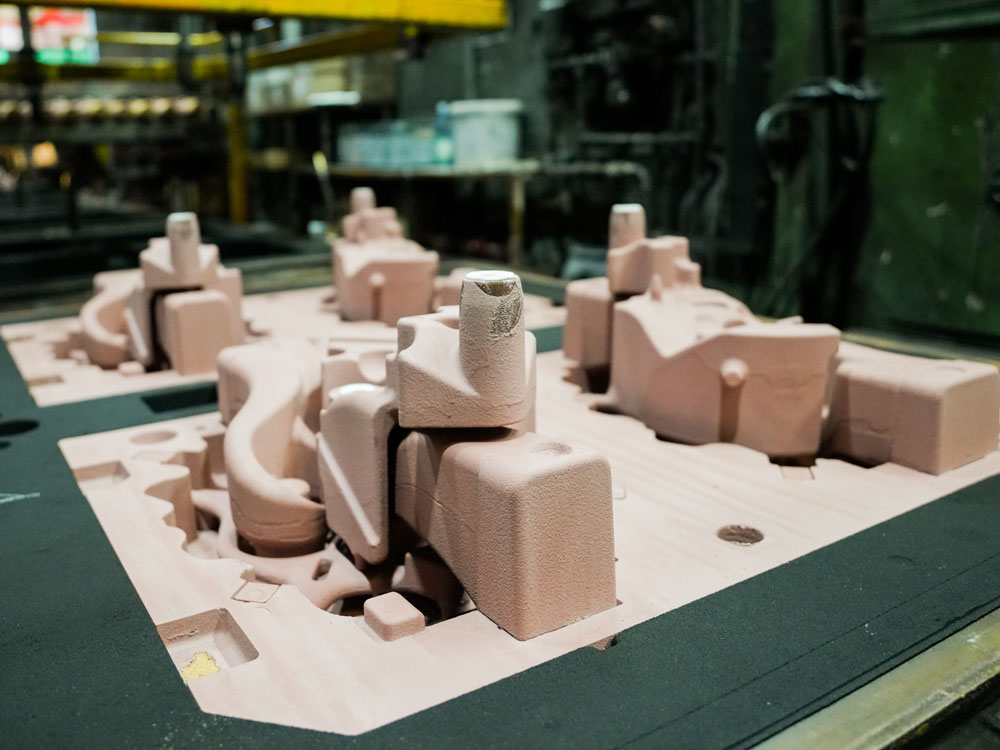

Luitpoldhütte is one of the most efficient foundries for machine casting in small and medium series. We are the specialist for heavy, complex and core-intensive castings up to 1100 kg made of gray cast iron (GJL), spheroidal graphite iron (GJS) and vermicular graphite (GJV).

Cast Iron Fabrication

at the melting shop

cast iron-

fabrication

at the-

melting shop

The melting process and technology are of particular importance in the production of cast iron. The optimum carbon content of the cast iron is ensured by the correct ratio of coke, cast iron scrap and steel scrap. Temperatures of around 1,500 °C are reached in the furnace.

Unique in its size

the Moulding Shop

We have recognized what makes us unique. And that is why we have focused on heavy, highly technical and core-intensive castings up to one ton. We cast demanding

parts in extraordinary sizes and have been meeting special customer specifications for years.

From the beginning on

until the finish

We are a full-service partner. We support customers with production-optimized design from the beginning and deliver an optimal product at the end, which must embrace the high quality standards we set for ourselves.

Innovation and people are always in focus, we use more and more robots to make the heavy work easier for employees.

The technical equipment of our cast end treatment includes: