craft and tradition

Innovation in progress

Initially founded in 1883 as a blast furnace plant, the first foundry was established in Amberg in 1911 under the name Luitpoldhütte. We stand for traditional craftsmanship and for constant further development and innovation. The name Luitpoldhütte stands for highest reliability and extraordinary quality standards. We look back on a company history of almost 140 years.

| 1883 |

| The blast furnace is founded |

| 1911 |

| The first foundry is set up with the name of "Luitpoldhütte" (in honour of the 90th birthday of Prince Regent Luitpold) |

| 1995 |

| A new management begins restructuring Luitpoldhütte. No more automotive. Focussing on agriculture, large engines, compressors, etc.. |

| 2008 |

| 125 years Luitpoldhütte |

| 2016 |

| Change in ownership structure: Luitpoldhütte as a limited liability company and belongs 100& to the OGEPAR-Group. OGEPAR-Group. |

Our Philosophy Is

Our Business: Castings

Our success triangle makes it clear: People are at the center. It is the people at Luitpoldhütte who meaningfully interlink the strategic, operational and communicative levels and fill them with life. Thus, the corporate culture of Luitpoldhütte forms the breeding ground on which visions, strategies and vital change processes grow and flourish. The prerequisite for this is comprehensive information, constant communication and the will to create value and break new ground.

Luitpoldhütte is aware of its responsibility towards the environment, and therefore environmental protection is also comprehensively anchored in our management system. In our quality, environmental and energy policy, we have set ourselves guidelines for improving our environmental performance.

Our Performance

Moves Machines Worldwide

We produce castings in gray iron, ductile iron and compacted graphite iron (CGI) from 100 to 1,000kg in small and medium series.

With our dedicated engineering team we are always open to develop projects in new markets

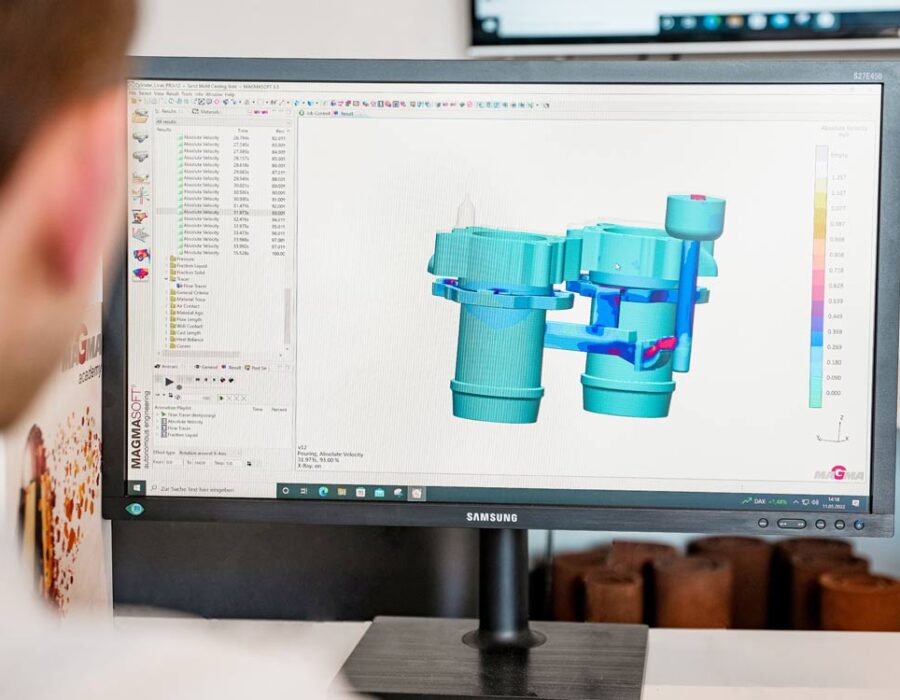

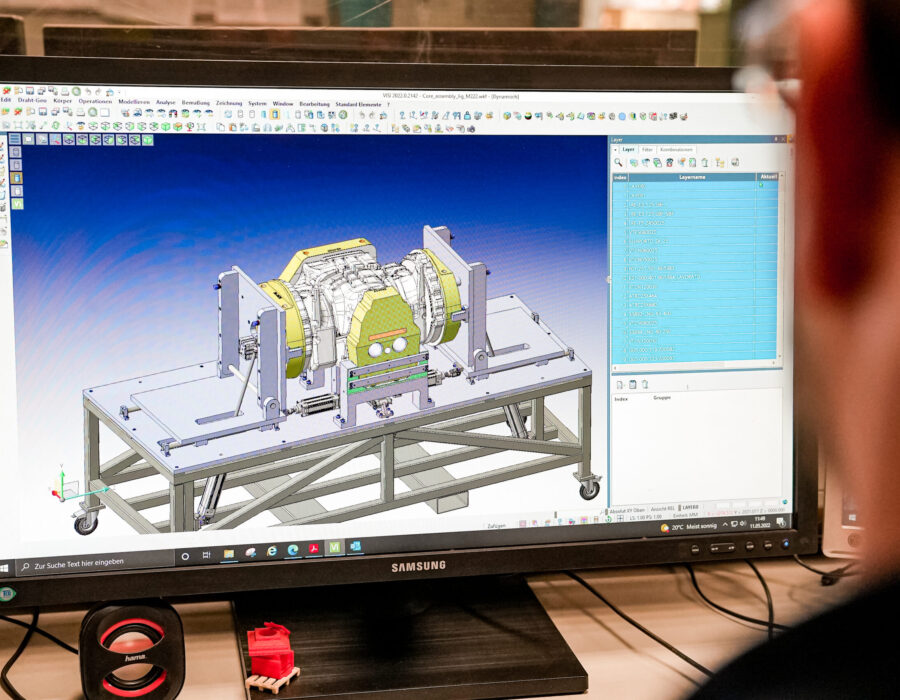

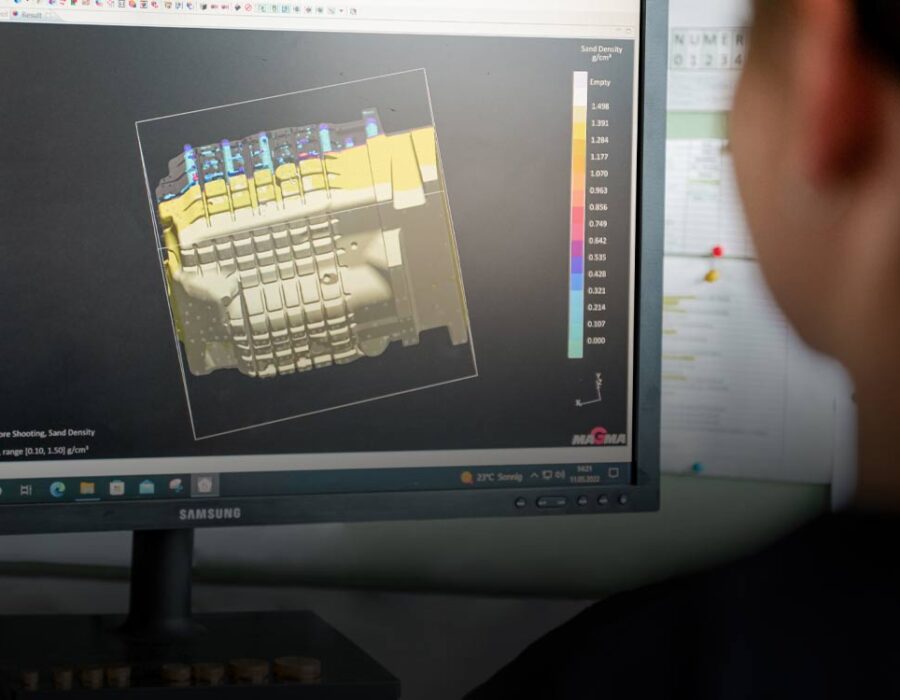

Our services for new projects include, among other things, professional consulting and support for casting design and the selection of the appropriate material. With our engineering team and our simulation capabilities with MAGMA SOFT (core shooting simulation, casting solidification stress simulation), we are ideally positioned for this. We also work with CREO and SolidWorks and can process all common 3D formats. In addition, we also offer machined castings with external partners.

Quality, Energy & Environment

The Superpower

The quality, environmental and energy awareness practiced in all areas of the Luitpoldhütte is also reflected in the ISO certificates. In addition to the quality and environmental certificate ISO 9001/14001, according to which the Luitpoldhütte has already been certified for many years, all requirements for the energy certificate ISO 50001 have also been officially fulfilled since 2013.

Our global footprint is

fabricating products that are endless in recycling